|

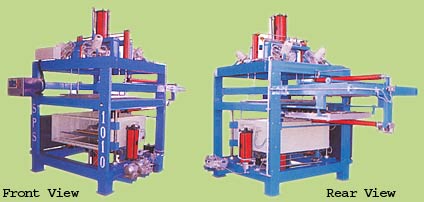

Special Purpose Thermoforming (SP and SPS Series) |

|

|

|

Product Details |

|

|

|

|

|

Thermoforming has now found diverse applications that few years ago were hard to fathom. The R & D division of Wonderpack has developed a very unique design for these type of machines and each of these has features that make them at par with the best available anywhere in the world. Customer's specific requirements were borne in mind during the design and fabrication of the SPS series machines. There are different techniques that are in use for the forming operation ...these being the Pre-blow, plug assist or a combination of these techniques.

The SPS series follows a simple operational sequence based on the vacumm forming principle. It is a unique state-of-the art machine, yet totally operator friendly.

• Comprehensive Control Panel: Close control at all stages is given by a particularly comprehensive range of control on a centralized panel. The setting up can be precisely suited to the works and materials. • Comprehensive Control Panel: Close control at all stages is given by a particularly comprehensive range of control on a centralized panel. The setting up can be precisely suited to the works and materials.

• Sandwich (Duplex) True Infrared Ceramic Heating System: Depending on different configuration and the thickness of the formed products we use True Infrared Ceramic Heating Elements with sandwich heating. As a result the heater surface radiates evenly and an evenly distributed heat pattern is easily obtainable even if it is in short distance. • Sandwich (Duplex) True Infrared Ceramic Heating System: Depending on different configuration and the thickness of the formed products we use True Infrared Ceramic Heating Elements with sandwich heating. As a result the heater surface radiates evenly and an evenly distributed heat pattern is easily obtainable even if it is in short distance.

• Single Start Button System: The operator has to only place a sheet of material in position and press a single Start button for complete production cycle to take place automatically.

•PLC Control System: All our SPS series machines are provided with PLC controls for precise and easy control of various operation parameters. •PLC Control System: All our SPS series machines are provided with PLC controls for precise and easy control of various operation parameters.

|

|

|

|

|

|

|

|

Other Features and Advantages |

|

|

|

• Automatic clamping and declamping mechanisms are used.

• Individual heater controls for optimum and efficient heating.

• Industrial cooling blowers are provided.

• Sheets upto a maximum thickness of 8 mm can be formed.

• European made infrared heaters with special reflectors.

• Heating plate height is adjustable.

• Wide choice of moulds.

• Robust construction ensuring longer life and minimum maintenance.

|

|

|

|

|

|

|

|

|

|

Product Details | Other Features | Tech Specs | Application | Business Enquiry | Main page |

|

|

|

|

|

|

|

For more information on any product or to obtain a rate quote, please complete the Business Enquiry Form, send an E-mail or Contact. |

|

|

|