|

|

|

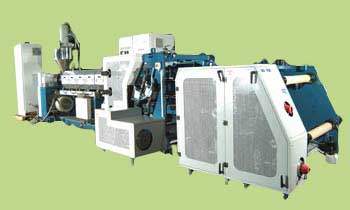

K-Series Extruders |

|

|

|

Product Details |

|

|

|

|

|

After having developed the unique Uniforma K Series thermoformer, need was felt to back it up with an extrusion unit that would qualitatively match the performance of the thermoformer. Thus evolved the K series Extruders. The continuous linear extrusion is synchronized to match the vertical cycles of thermoforming using an indigenous technology. This enables complete control of the process and delivers high quality products.

Features of the Sheet Line Extrusion Unit:

• In-built thrust housing gear box with compact base: Leads to better load distribution capacity and stability, thus ensuring better processing of material.

• Nitro alloy steel barrel and screw: Barrel and screw made of high quality special alloy steel ensure long life of the unit and deliver better melt quality.

• Plunger type screen changer: Screen can be changed even when the sheet line extruder is in operation. The cycle time is for changing this filtration screen is minimal.

• Flexible Feed block: Unique design of feed block made up of special alloy steel enables the user to add one or more extruders for multi-layer sheets.

• Gear pump adaptability: Incorporating gear pump improves quality and thickness tolerance of finished sheet and increases throughput of the line. It also provides a surge free and constant melt flow of material and plastification.

• 'T' Die FLEXILIP: Constructed of P 20 material, this coat hangar type Flexilip T Die helps in optimization of die temperature control system in terms of energy saving. Further, good and consistent sheet quality is ensured over a larger period of life.

• Polishing stack roller assembly: Consists of 3 roll vertical stack with a Gear mechanism. The outer surface of the roller is induction hardened upto case depth of 3mm and mirror polished with a surface finish of upto 3Ra and hardness of upto 58 HRC. Each polishing roll has an individual temperature control.

• Heating-cooling system for chrome roller: Microprocessor based temperature controller with water-based circulation system ensures high setting accuracy. Temperature is maintained accurately at ± 1° celcius across the roller width.

• Heater control: Dual PID loops offer optimum control of the heating and cooling zones of the machine. The heater zones can be set, monitored and tuned through the MMI for precision.

|

|

|

|

|

|

|

Product Details | Tech Specs | Application | Business Enquiry | Main page |

|

|

|

|

|

|

|

For more information on any product or to obtain a rate quote, please complete the Business Enquiry Form, send an E-mail or Contact. |

|

|

|

|